Cement Mill Shell Liners

Cement Mill Shell Liners Manufacturer in India

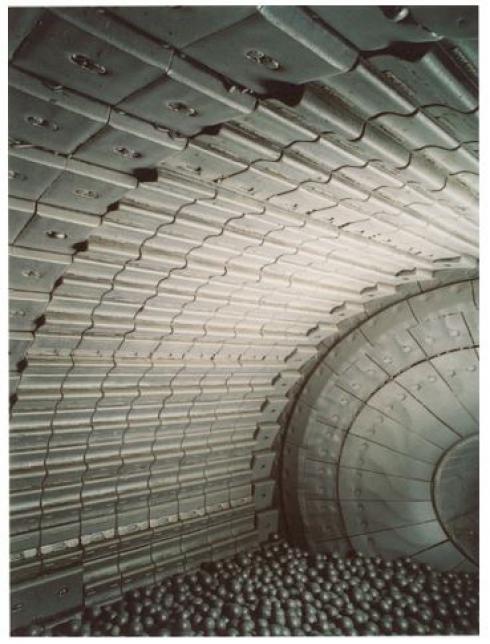

Leading Cement Mill Shell Liners Manufacturer – PA Steel Co.

PA Steel Co. is a trusted manufacturer of high-quality cement mill shell liners, catering to industries across Kolkata, West Bengal, Jharkhand, Bihar, Odisha, Chhattisgarh, Assam, Madhya Pradesh, and Nepal. With years of expertise in precision engineering, we provide durable, wear-resistant liners that enhance the efficiency and longevity of cement mills.

Table of Contents

ToggleThere are several types of cement mill liners: feed-end-liners, lifting-liners, classifying liners. P A Steel Co. the optimum design and alloy for Cement Mill Shell Liners to give the best mill protection and grinding efficiency. This is done according to a variety of factors such as Cement Mill Shell Liners type, rotation speed, maximum ball diameter, grinding media filling degree, material ground and mill drilling.

The key benefits of this include an increased lifetime, a handling device available in case of heavy weight liners and a design adapted to mill operating parameters. Our purpose is to protect the flange or mill shell and also avoid any projection of balls against the linings. We are one of leading Cement Mill Shell Liners Manufacturer in India.

The P A Steel Co. Manufactures Inlet Discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Cement Mill Shell Liners used in the Cement industry. Work at its own Research facilities, together with proven experience in the field, has enabled The P A Steel Co.to develop a range of liners that are tailored to operate at maximum cost-effectiveness for the conditions of the Cement Mill Shell Liners.

The benefits of this experience include:

- Grinding efficiency of second chamber maintained at optimum level

- A steady flow of material is ensured and a very fine ball charge can also be used

- Significant reduction in wear rates of balls and the liners

- Lower operating costs due to increased working life

- Reduced downtime required for replacement of liners

Key Features of Our Cement Mill Shell Liners

- High Wear Resistance: Manufactured from premium-grade materials, our liners offer superior resistance to abrasion and impact, ensuring longer service life.

- Customizable Designs: We offer a variety of liner designs to suit different mill types and grinding conditions, allowing for optimized performance.

- Energy Efficiency: Our liners are designed to improve energy transfer to the grinding media, enhancing the overall efficiency of the milling process.

- Ease of Installation: Pa Steel Co’s liners are easy to install and replace, minimizing downtime and maximizing productivity.

- Cost-Effective: With extended wear life and reduced maintenance needs, our liners offer a cost-effective solution for cement mills.

Product Specifications

| Product | Material | Application | Benefits |

|---|---|---|---|

| Cement Mill Shell Liners | High Chrome Iron | Cement Mills | High wear resistance, improved grinding efficiency |

| Cement Mill Head Liners | Manganese Steel | Cement Mills | Superior impact resistance, easy installation |

| Cement Mill Discharge End Liners | Ni-Hard Alloy | Cement Mills | Enhanced durability, reduced maintenance |

| Cement Mill Grate Plates | Alloy Steel | Cement Mills | Optimized energy transfer, extended service life |

Applications of Cement Mill Shell Liners

Our cement mill shell liners are widely used in various types of cement mills, including:- Ball Mills: Providing excellent wear resistance and enhancing the grinding process.

- Tube Mills: Ensuring efficient energy transfer and consistent product quality.

- Rod Mills: Offering superior impact resistance and extending the service life of the mill.

Quality Assurance

At Pa Steel Co, we are committed to delivering products that meet the highest standards of quality and performance. Our cement mill shell liners are subjected to rigorous testing and quality control processes to ensure they meet the specific requirements of your milling operations.Global Reach

Pa Steel Co is headquartered in India, with a strong distribution network across the country and beyond. We serve clients in various regions, ensuring that our premium cement mill shell liners are available wherever your operations are located.Contact Us

For more information about our Cement Mill Shell Liners, or to request a quote, please contact Pa Steel Co today. Our team of experts is ready to assist you with your specific needs, providing customized solutions that meet the demands of your cement milling operations.Frequently Asked Questions (FAQs)

Our cement mill shell liners are made from high-grade materials, including high chrome iron, manganese steel, and Ni-Hard alloy, each selected for their specific wear and impact resistance properties.

The choice of liner depends on several factors, including the type of mill, the grinding process, and the operating conditions. Our team at Pa Steel Co can help you select the right liner based on your specific needs.

Our liners provide high wear resistance, improved grinding efficiency, reduced maintenance costs, and extended service life, making them a cost-effective solution for cement milling operations.

The replacement frequency depends on the milling conditions, the material being processed, and the wear resistance of the liner. Regular inspections can help determine the optimal replacement schedule.

Yes, we offer customizable liner designs to suit different mill types and specific operating conditions, ensuring optimal performance and longevity.

We deliver our products across India, including regions like Kolkata, Bihar, Odisha, and other states, as well as worldwide, ensuring that our high-quality liners are available wherever they are needed.

You can place an order by contacting us directly via our website, email, or phone. Our team will assist you with product selection, pricing, and any other inquiries you may have.

Our liners are manufactured in compliance with international standards, ensuring they meet or exceed industry requirements for quality and performance.